PEM Electrolyzers

PEM Electrolyzers

Introduction to PEM Electrolyzers

Understanding the Role and Functionality of PEM Electrolyzers in Hydrogen Production

Definition of PEM Electrolyzers

Proton Exchange Membrane (PEM) electrolyzers are essential technology for producing hydrogen efficiently and sustainably.

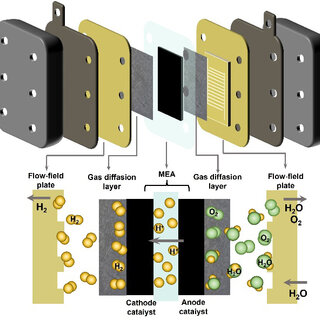

Functionality

These systems utilize electrical energy to facilitate the electrolysis process, splitting water into hydrogen and oxygen gases.

Role of PEM

The PEM acts as both a separator and an electrolyte, allowing protons to pass while blocking gases, ensuring efficient hydrogen generation.

High Efficiency

PEM electrolyzers are known for their high efficiency rates, maximizing hydrogen output from the input energy provided.

Rapid Response Times

These systems can quickly adjust their output in response to fluctuations in energy supply, making them ideal for renewable energy integration.

Importance in Renewable Energy

Integrating PEM electrolyzers with renewable energy sources is crucial for achieving a sustainable energy future and reducing carbon emissions.

Contribution to Green Energy Systems

By producing green hydrogen, PEM electrolyzers contribute significantly to the transition towards cleaner energy systems and fuel sources.

PEM Electrolyzers

Key Materials in PEM Electrolyzers

Overview of critical components

Electrodes

Electrodes are typically made from precious metals like platinum, which are critial for facilitating the electrode reactions necessary for efficient hydrogen production.

Electrolyte Membranes

These Membranes are usually composed of a proton-conductive polymer. They play a vital role in separating gases while enabling the conduction of protons, ensuring the electrolyzer functions effectively.

Catalysts

Catalysts enhance the reaction rates in the electrolyzer. Often made from rare and expensive materials, they are essential for optimizing performance and efficiency.

Bipolar Plates

Bipolar Plates are crucial for conducting electrical current and managing heat and gas flow. The choice of robust and conductive materials is essential for the durabilty and efficiency of the electrolyzer.

Electrode Materials

Current Status of Electrode Materials

Overview of Challenges and Research Directions

Introduction to Electrode Materials

Electrode materials play a crucial role in the function of Proton Exchange Membrane (PEM) electrolyzers, facilitating the conversion of electricity to hydrogen.

Importance of Platinum

Platinum is the primary choice for electrode materials due to its exceptional catalytic efficiency, essential for optimal electrolyzer performance.

Challenges with Platinum

Despite its advantages, platinum’s high cost and limited availability create significant barriers for widespread use in hydrogen production.

Research Focus: Reducing Platinum Loading

Current research aims to minimize the amount of platinum used in electrodes, seeking to maintain efficiency while decreasing costs.

Exploring Alternative Materials

Researchers are investigating platinum alloys and non-precious metal catalysts as viable alternatives to improve performance and reduce costs.

Goals of Current Research

The overarching goal is to enhance the performance of electrolyzers while minimizing the use of expensive and scarce materials.

Proton conductive

Electrolyte membranes must facilitate efficient proton transport to enhance performance in PEM electrolyzers.

Catalyst Overview

Catalyst Materials Overview

Understanding the Role and Development of Catalyst Materials in PEM Electrolyzers

Importance of Catalysts

Catalysts play a pivotal role in enhancing the efficiency of electrochemical reactions in PEM electrolyzers, optimizing energy conversion.

Current Materials

Platinum and iridium oxides are the preferred catalysts due to their exceptional activity and stability under operational conditions.

Goals of Research

The primary objective is to reduce material costs while ensuring that the efficiency and stability of the catalysts remain competitive with current options.

Research into Alternatives

Researchers are investigating earth-abundant materials such as nickel and iron to create costeffective catalysts without compromising performance.

Challenges Faced

Despite their effectiveness, the high cost and limited supply of platinum and iridium present significant barriers to widespread adoption.

Bipolar Plates

Bipolar Plates and Their Importance

Key Components in PEM Electrolyzer Efficiency and Cost Management

Definition of Bipolar Plates

Bipolar plates are crucial components in PEM electrolyzers, facilitating electrical currents while managing heat and mass transfer.

Impact on Efficiency

These plates significantly affect the efficiency of PEM electrolyzers, influencing overall energy consumption and performance.

Cost Considerations

The choice of materials for bipolar plates directly impacts the manufacturing costs of PEM electrolyzers.

Traditional Materials: Graphite

Historically, bipolar plates have been made from graphite, which presents challenges such as high weight and costly machining processes.

Emerging Alternatives: Metals

Research is focusing on using metal-based alternatives like stainless steel and titanium, which may reduce costs and enhance durability.

Advantages of Metal Plates

Metal bipolar plates offer potential benefits including lower weight, improved strength, and enhanced resistance to corrosion.

Material Lifespan

Material Durability and Lifespan

Understanding the Factors Influencing Material Longevity in PEM Electrolyzers

Importance of Material Durability

Material durability is essential for the efficient operation of PEM electrolyzers, directly impacting their longevity and reliability in hydrogen production.

Operational Conditions Affecting Durability

Factors such as temperature extremes, high pressure, and exposure to corrosive chemicals contribute to the degradation of materials used in electrolyzers.

strategies for enhancing durability

Implementing protective coatings, utilizing advanced material compositions, and adhering to optimized operational protocols can significantly improve the lifespan of electrolyzer components.

Benefits of Enhanced Durability

Improved material durability leads to lower operational costs and enhances the economic viability of hydrogen production, making it a sustainable energy solution.

Material Selection Criteria

Evaluation Criteria for Material Selection

Key Factors for PEM Electrolyzers

Cost

Materials must be economically viable for large-scale production to ensure affordability and accessibility in the market.

Efficiency

High performance is essential in materials to minimize energy consumption, directly affecting the overall efficiency of PEM electrolyzers.

Durability

Materials need to withstand operational stresses and have extended lifespans to reduce maintenance costs and enhance reliability.

Scalability

The availability of materials in sufficient quantities is crucial for widespread adoption and mass production of PEM electerolyzers.

Electrode Innovations

Innovations in Electrode Materials

Recent advancements aimed at cost reduction and performance enhancement

Platinum Alloys

These alloys enhance catalytic activity while significantly reducing the amount of platinum needed, thus lowering costs.

Nanostructured Materials

Utilizing nanostructured materials increases the surface area available for reactions, improving catalytic efficiecy and overall performance.

Hybrid Materials

These materials combine metals with carbon-bassed supports to enhance conductivity and durability, making them more effective in applications.

Membrane Innovations

Advancements in Membrane Technologies

Key Innovations for PEM Electrolyzers

Composite Membranes

These membranes combine various materials to significantly enhance their conductivity and durability, which is essential for efficient electrolyzer performance

Hydrocarbon-based Membranes

Utilizing hydrocarbon materials, these membranes present opportunities for cost reductions while also offering notable environmental advantages.

High-temperature Membranes

These membranes facilitate operation at higher temperatures, leading to greater efficiency in hydrogen production processes.

Catalyst Innovations

Catalyst Innovations

Emerging Catalyst Technologies

Innovations in PEM Electrolyzers

Non-precious Metal Catalysts

Utilizing abundant materials like nickel and iron instead of expensive noble metals, reducing cost and enhancing accessibility.

Bimetallic and Alloy Catalysts

Combining two or more metals to leverage synergistic effects that enhance catalytic activity and stability.

Enzyme-inspired Catalysts

Mimicking natural enzymatic processes to achieve higher efficiency and selectivity in chemical reactions.

Potential Impact

These emerging technologies could revolutionize catalyst design, significantly lowering production costs and paving the way for more sustainable energy solutions.

PEM Trends

Future Perspectives and Trends in PEM Electrolyzer Materials

Key Trends Shaping the Future

Sustainability

Increasing focus on environmentally friendly materials and processes to reduce ecological impact.

Cost Reduction

Ongoing efforts to lower material and production costs to enhance economic viability.

Performance Optimization

Continuous improvement in efficiency and durability of PEM electrolyzer materials.

Integration with Renewable Energy

Enhancing compatibility with intermittent renewable energy sources for better energy management

Material Selection

Balanced Perspectives on Material Selection

Key Considerations in Choosing Materials

1. Cost vs. Performance

Balancing affordability with high efficiency is crucial for successful material selection in PEM electrolyzers, as it directly impacts production costs and performance outcomes.

2. Durability vs. Scalability

Ensuring a long lifespan of materials is essential, yet it must not hinder the ability for mass production. Finding this balance is vital for the scalability of electrolyzer technology.

3. Innovation vs. Proven Technologies

The choice between adopting cutting-edge materials and relying on established solutions poses a strategic dilemma. It’s important to evaluate the potential benefits and risks associated with each option.

4. Complexity of Material Selection

The material selection process is multifaceted, requiring in-depth analysis of various factors to ensure sustainable hydrogen production while meeting industry demands.

Importance of Material Development

Developing and optimizing key materials for PEM electrolyzers is crucial for advancing hydrogen

Diverse Material Landscape

The current landscape includes a variety of materials, each presenting unique advantages and challenges that must be navigated to enhance

Need for Ongoing Research

Continuous research and innovation are essential to overcome existing limitations in materials

Explore Hydrogen Production Advancements

Join us in exploring the cutting-edge advancements and material innovations that are shaping the future of hydrogen production through PEM technology.